Essential Financial Management Practices of Biotech Companies – A 5-Part Series

Article 2: Automate Batch/Lot Tracking to Ensure Traceability

How quickly and effectively can you act?

One of the ingredients used last month may have been contaminated. How much is still in inventory? How much was used in products that were finished and shipped? Where were they shipped? Is the ingredient in use in current batches?

The stress and pressure of a recall are acute. Having to deal with a recall via spreadsheets is an even more painful nightmare. Having to sift through endless paper, stashed in multiple file cabinets? That’s a crisis situation that may have dire consequences.

On the other hand, if you could log into your ERP/Warehouse & Inventory management system, and run a quick query, response time is quicker, giving you and the company better control over the situation.

You understand how important traceability is. Manual systems – whether paper-based or spreadsheet-driven – put your organization at risk. You simply cannot react at an optimal level.

Manual versus modern

In the second part of our 5-part series, the subject is automating batch/lot tracking to ensure traceability. Technology has allowed the affordable automation of even the most complex workflows.

Traceability is the foundation for compliance and transparency. If the processes for traceability are manual and paper-based – you are operating on a shaky, questionable foundation. From raw materials through finished goods, accurate tracking of all inputs to batches and lots is critical to assure investors and regulators of full traceability.

Paper-based systems can be compromised. Paper documents are easily damaged or destroyed. Paper documents are easy to mistakenly place in the trash or recycling bin. And, if misfiled, a paper document might be never be found. It’s a process guaranteed to break down at some point – inflicting frustration in the best case scenario, catastrophe in the worst case scenario.

3 benefits of automation

There are three key ways that automation can serve your organization: consistent quality assurance processes; consistent tracking and documentation; and Investor confidence due to reliable processes.

- Consistent quality assurance processes – a digital platform designed specifically for biotech provides a single source of information to reliably support compliance. Track ingredients by lot and batch across the full lifecycle in a unified system.

- Consistent tracking and documentation – through automated processes, your organization can trace ingredients across process stages and quality checks. Manage quality documentation from cradle to grave in a single unified system.

- Reliable processes assure investors – Tracking ingredients across products, process stages, and quality checks by lot or batch minimizes the risk of non-compliance and simplify managing audits. With integrated quality and compliance management capabilities, you can assure investors of consistent, verifiable results.

A unified system

When it comes to ERP/Warehouse & Inventory management system software, there are two configuration models: a complete suite of modules by a single publisher model or a best-in-class or best-of-breed solution model.

Both models can provide what we are calling a unified system.

Suite integration – In the past, the suite model provided the most integration between functions because the modules and the interfaces were designed by the same publisher. Integration was seamless but the drawback was the relative strength of each module. The suite might have a powerful manufacturing module but a bare-bones accounting module – or vice versa.

It was difficult then, and even more difficult now, for publishers to have deep domain knowledge in multiple functional areas.

Best-of-breed integration – The advent of the cloud and open architecture have given rise to a unified system approach that employs best-of-breed software applications. This model ensures that financial accounting has the best accounting system, sales have the best CRM system, and operations have the best warehouse and inventory management system, etc.

“We are proponents of the best-of-breed integration approach for two reasons,” explains Philip Massey, CPA and founder of Massey Consulting. “The first reason is pragmatic: departments tend to buy applications first and think about integration later. The second reason is that best-of-breed is as described – it means you’re free to choose the best application for each department/functional area.”

Philip Massey (Massey Consulting) and James Wang (QStock Inventory) share some examples of how a best-of-breed ERP/Warehouse & Inventory management system combine to provide biotech and life science companies with the best solutions for accounting, inventory, lot/serial traceability, etc.

“The integration between QStock and Sage Intacct gives biotech leadership in accounting and operations deep web services level integration,” explains Wang. “There are subledger touchpoints with dimensional support. This means that there is real-time access to critical information.”

“The other benefit is streamlined, efficient workflows,” explains Wang. “Integration of ERP/Warehouse & Inventory management systems means the elimination of many manual processes, re-keying of data, and the inefficiencies of paper-based systems.”

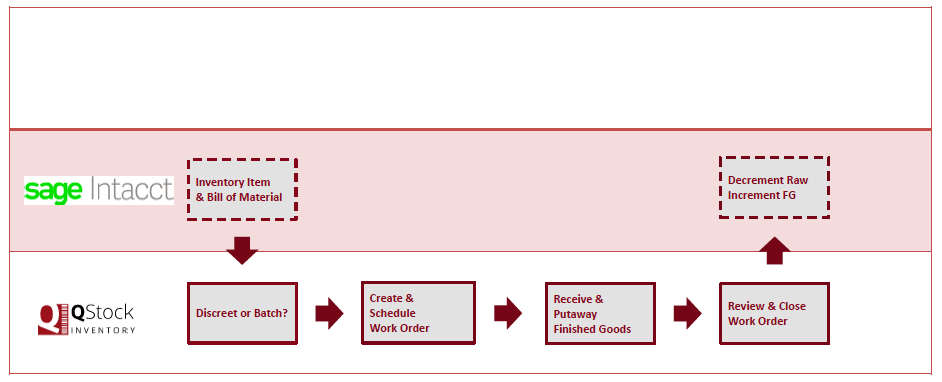

Optimized Work Order Build Process

In this workflow, the biotech company has their inventory and BOM master records originate in Sage Intacct. And those master records are used by QStock when a production order is started. This is an example of two best-of-breed solutions sharing the same records. This integration helps the organization use available inventory, easily see quantity levels to know if they can start production (avoid ordering unnecessary ingredients or conversely being alerted to the need order needed ingredients).

In this workflow, the biotech company has their inventory and BOM master records originate in Sage Intacct. And those master records are used by QStock when a production order is started. This is an example of two best-of-breed solutions sharing the same records. This integration helps the organization use available inventory, easily see quantity levels to know if they can start production (avoid ordering unnecessary ingredients or conversely being alerted to the need order needed ingredients).

This gives the biotech team the capability to track (within Sage Intacct or QStock) which raw materials were used in which lots. You have lot and serial number tracking capabilities throughout this Work Order Build Process.

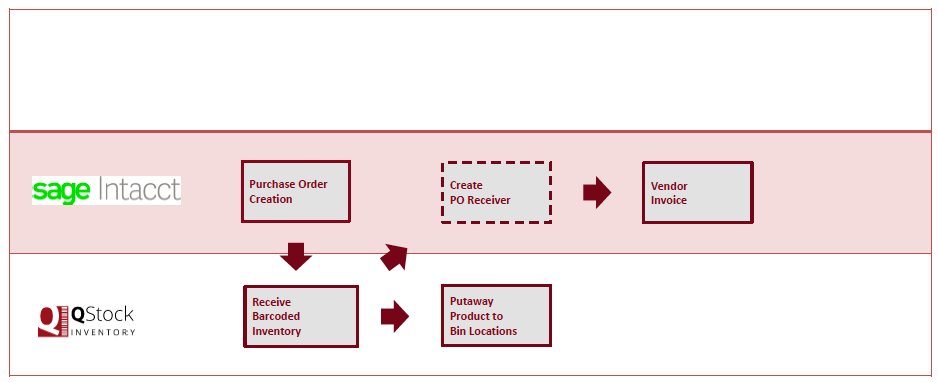

Optimized Procure to Pay Process

This example depicts an optimal procure-to-pay process with the creation of the Purchase Order in Sage Intacct. The integration between Sage Intacct and QStock allows QStock to receive items, using handhelds to scan inventory – this is faster and more accurate than paper-based processes. At this point users have the option of creating receipt of goods in Intacct, while QStock ensures the inventory in place in the correct warehouse bin locations. Automation within Sage Intacct completes the process by turning the PO receipt into a Vendor Invoice, facilitating vendor payment.

This example depicts an optimal procure-to-pay process with the creation of the Purchase Order in Sage Intacct. The integration between Sage Intacct and QStock allows QStock to receive items, using handhelds to scan inventory – this is faster and more accurate than paper-based processes. At this point users have the option of creating receipt of goods in Intacct, while QStock ensures the inventory in place in the correct warehouse bin locations. Automation within Sage Intacct completes the process by turning the PO receipt into a Vendor Invoice, facilitating vendor payment.

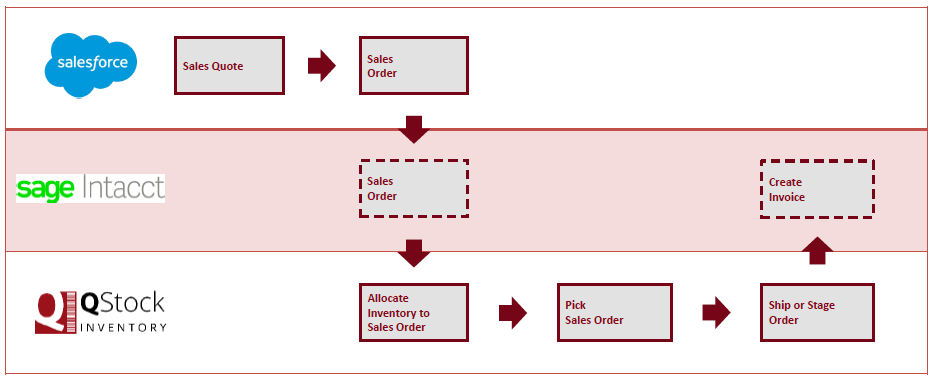

Optimized Lead to Cash Process

In this workflow, three best-of-breed solutions (CRM, Accounting, Warehouse & Inventory) streamline the Lead to Cash Process.

Your sales team will utilize Salesforce (the most widely used CRM systems) to manage leads, opportunities, and orders. Upon signature and approval, those orders are moved to Sage Intacct, which then triggers QStock to begin allocating inventory and to initiate the picking process. Again, manual, error-prone processes are eliminated, as hand-held scanners are used to pick the appropriate items and record lot numbers, bin locations, and more.

Once all items are picked and the order is fulfilled and shipped, using the automation in QStock, Sage Intacct is notified and creates an invoice. Sage Intacct can email the invoice and receive electronic payment – which completely eliminates paper from the process.

Conclusion

“You have the merging of two or more major universes with a best-of-breed approach. You’ve got comprehensive reporting that can enable quick response and correction if there’s a problem like a recall,” says Wang. “But what’s more visible and immediate are the day-to-day improvements in processes and results. That means being more competitive if the company is revenue-driven. Better performance and strong reporting mean no hiccup in funding for companies that are startups.”

“When a biotech company takes a best-of-breed approach to information systems, there is a groundswell of improvement,” explains Massey. “Managers, throughout the organization, are better able to run their department because they have greater insight into their functional areas. We’ve seen countless examples within our customer-base of the dramatic improvements that are possible when CFOs have real-time, accurate data. They can better address both problems and opportunities.”

Read Part 1: Accurately Track Costs with Project Accounting

Read Part 3: Support Flexible Reporting, Forecasts and Budgeting